Does North Carolina Provide Money For Recycling

State provides funding for 20 recycling projects

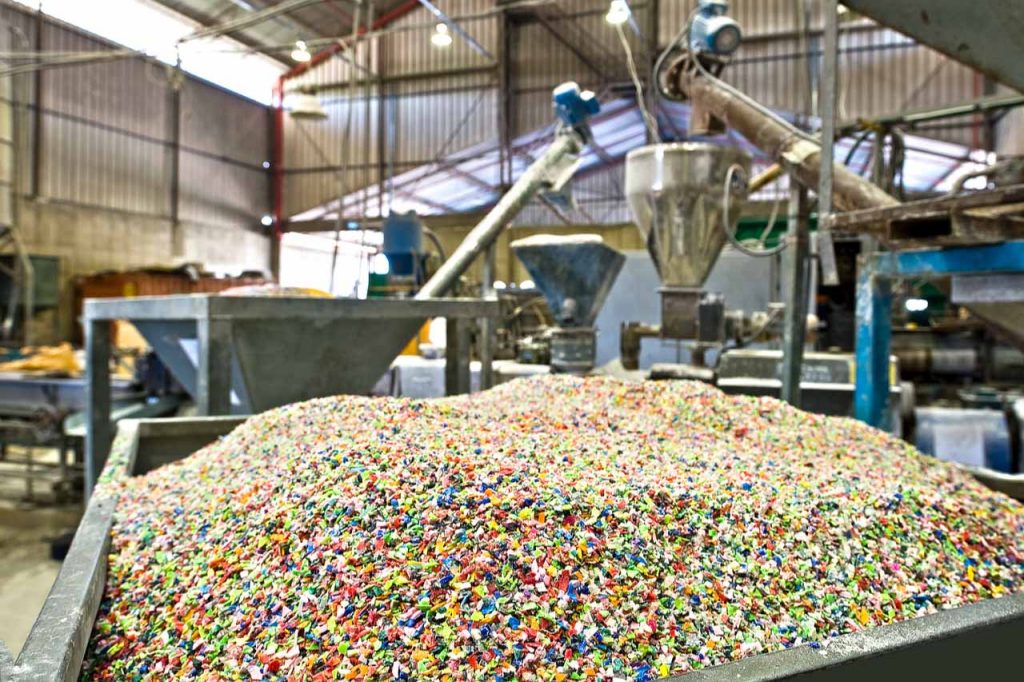

Officials estimate that 20 projects receiving grants will collectively divert well-nigh 44,000 tons of material from landfills each year. | ImagineStock/Shutterstock

North Carolina recently awarded hundreds of thousands of dollars in grants to help divert mixed recyclables, organics, paper, plastic and other materials from landfills.

The North Carolina Department of Environmental Quality (NC DEQ) provided nearly $666,000 in recycling business development grants to xx companies.

"Recycling businesses are valuable contributors to Due north Carolina'southward long-term economic development while working toward a cleaner, more sustainable environment," Jamie Ragan, manager of the Partition of Environmental Aid and Customer Service, stated in a press release. "The projects funded by these grants will create jobs and redirect recyclables back into the economy, thereby diverting materials from the waste matter stream."

The following projects, organized by fabric handled, received funding.

C&D debris

- Carolina Concrete ($25,000): The visitor will purchase a permanent office edifice to expand the visitor's client base for concrete recycling.

Mixed recyclables

- American Recycling ($threescore,000): The company will buy a new baler to reduce costs and increase efficiency at its MRF.

- East Coast Consolidated ($xxx,000): The company will purchase a carve up-trunk truck and recycling containers to expand curbside recycling service.

- Merely Dark-green Recycling ($thirty,000): The company will purchase a rear-loading compacting truck to collect residential and commercial recyclables more efficiently and expand service.

Organics

- Crown Town Compost ($32,130): The company volition purchase a refrigerated walk-in trailer, curbside roll-out bins, a compost mixer and a compost sifter to expand the company's organics recycling services.

- Gallins Family Subcontract ($24,500): The company will purchase a front-stop loader to increase equipment capacity and processing productivity at its handling site for recycling nutrient and organic waste.

- Ingram Woodyards ($15,000): The company will purchase an open-elevation chip van to aggrandize the company's wood droppings recycling capacity.

Paper

- Cascades ($60,000): The company volition purchase a detrasher and trommel system to separate droppings from recyclable materials and improve efficiency for recycling mixed newspaper.

- Orangish Recycling Services ($x,000): The company will purchase additional drove containers to expand the visitor's cardboard collection service in the Triangle surface area.

Plastics

- AEIPLUS ($40,000): The company will purchase launder line equipment to clean contaminated agricultural plastics as part of the moving picture recycling procedure.

- Bromley Plastics ($60,000): The company will purchase a plastic shredding system to increase chapters.

- Articulate Path Recycling ($40,000): The visitor will buy a system to reprocess cloth leap for landfill to recover greater amounts of recyclable plastic.

- High Cube ($25,000): The company volition purchase a foam densifier to expand its post-commercial expanded polystyrene and polyethylene recycling services.

- Pelican Packaging ($40,000): The visitor will rebuild a plastic shredder and purchase both a horizontal baler and forklifts to expand the visitor's industrial plastics recycling chapters.

- Plastic Materials ($60,000): The company will buy a larger building to increase its power to recycle picture show and rigid plastic flake materials.

- RePolyTex ($30,000): The visitor will buy molding equipment to manufacture plastic "plywood" sheets made from e-plastics and other mixed plastics.

- Resource Material Handling and Recycling ($12,000): The visitor will purchase a cyclone separation machine to amend the quality of regrind.

- Wellmark Plastics ($30,000): The visitor will purchase an optical sorter to separate and produce higher-value recycled resins.

Textiles

- Green Zone Recycling ($12,000): The company will buy an automated baler and collection containers to help in textile collection and recycling.

- Industrial Commons ($30,000): The company will purchase a conveyor and baler to more efficiently process textiles for recycling.

Grant recipients are required to invest at least a 50% cash lucifer. The grant recipients program to invest over $2 million of their own coin.

Annually, the projects above are anticipated to divert from landfills 6,000 tons of physical, 3,550 tons of mixed recyclables, 14,250 tons of nutrient scraps and wood debris, 3,156 tons of mixed paper and cardboard, 15,387 tons of post-industrial and post-consumer plastic, and 1,223 tons of textiles, according to NC DEQ data.

A version of this story appeared in Plastics Recycling Update on May six.

More than stories near local programs

- Local programs share tips for toll-effective recycling outreach

- Keeping municipalities whole

- Diversity, equity and inclusion vital to future operations

Source: https://resource-recycling.com/recycling/2020/05/12/state-provides-funding-for-20-recycling-projects/

Posted by: billerovertaker.blogspot.com

0 Response to "Does North Carolina Provide Money For Recycling"

Post a Comment